Spring vibration isolator technology is a crucial tool for maximizing equipment performance in various industries. By effectively reducing vibrations and noise, spring vibration isolators help to enhance the efficiency and lifespan of equipment. In this article, we will delve into the benefits and applications of spring vibration isolator technology, and how it can significantly improve the performance of industrial machinery.

Spring vibration isolator technology is designed to minimize the transmission of vibration and noise from equipment and machinery. By effectively isolating vibration, this technology helps to maximize the performance and lifespan of equipment. The use of spring isolators can also reduce the need for maintenance and repairs, saving time and money for businesses. These isolators are commonly used in a wide range of industries, including HVAC, manufacturing, and power generation, to ensure smooth and efficient operation of equipment. By implementing spring vibration isolator technology, businesses can improve equipment performance and create a better working environment for their employees.

Spring vibration isolator technology helps to minimize the transmission of vibration and noise from equipment and machinery, ultimately maximizing performance and extending the lifespan of the equipment. By effectively isolating vibration, this technology reduces the need for maintenance and repairs, saving both time and money for businesses. It is widely used in industries such as HVAC, manufacturing, and power generation to ensure smooth and efficient operation of equipment. Implementing spring vibration isolator technology can significantly improve equipment performance and create a better working environment for employees.

Understanding the Function of Spring Vibration Isolators

Spring vibration isolators are a type of mechanical device designed to reduce or eliminate the transmission of shock, vibration, and noise from machinery and equipment to the surrounding environment. They work by using a spring element to suspend the equipment, isolating it from the surrounding structure and minimizing the transfer of vibration. These isolators are commonly used in HVAC systems, industrial machinery, generators, and other equipment that generates vibrations during operation. They are particularly effective in reducing low-frequency vibrations, which can be especially damaging to both equipment and nearby structures. By understanding the function of spring vibration isolators, engineers and facility managers can select and install the appropriate isolators to effectively mitigate vibration and its associated effects. This can help to improve equipment performance, reduce maintenance costs, and create a more comfortable and safe working environment.

The Importance of Spring Vibration Isolators in Industrial Machinery

Spring vibration isolators are crucial in industrial machinery as they help reduce the transmission of vibration and noise in equipment. By minimizing the impact of vibrations, the longevity and efficiency of the machinery is increased, reducing maintenance and repair costs. Furthermore, spring vibration isolators also enhance the safety of workers by preventing the transfer of excessive vibrations to the surrounding environment. Overall, the use of spring vibration isolators in industrial machinery is essential for maintaining optimal performance, safety, and productivity.

Choosing the Right Spring Vibration Isolator for Your Equipment

small vibration isolation mounts

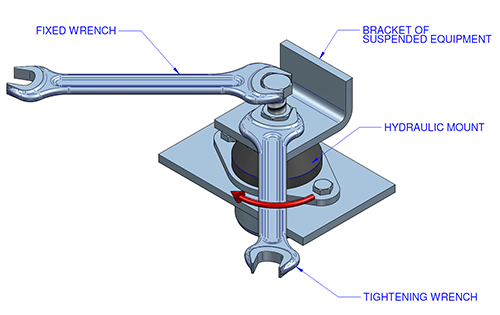

Selecting the appropriate spring vibration isolator for your equipment is crucial in order to minimize noise, vibration, and shock. Factors to consider include the weight and size of the equipment, as well as the frequency and amplitude of the vibrations. It's important to choose isolators with the right spring rate and natural frequency to effectively isolate the equipment from external forces. Additionally, consider the environment in which the equipment will be operating, as certain isolators may be more suitable for harsh or corrosive conditions. Regular maintenance and monitoring of the isolators is also essential to ensure proper functioning over time.

Common Applications of Spring Vibration Isolators in Engineering

Spring vibration isolators are commonly used in engineering for a variety of applications, such as: 1. Industrial machinery: Spring vibration isolators are used to reduce the transmission of vibration and noise from industrial machinery to the surrounding environment, helping to create a quieter and more pleasant work environment. 2. HVAC systems: Vibration isolators are used in heating, ventilation, and air conditioning (HVAC) systems to reduce the transmission of vibration and noise from the equipment to the building structure, minimizing disturbance to occupants. 3. Power generation: Spring isolators are used to support and isolate equipment in power generation facilities, such as generators, compressors, and pumps, to prevent the transmission of vibration to the surrounding structure and minimize equipment wear and tear. 4. Transportation: Spring isolation systems are used in transportation applications, such as rail and automotive, to reduce the transmission of vibration and noise from the vehicle to the passengers, providing a smoother and quieter ride. 5. Construction: Vibration isolators are used in the construction of buildings and bridges to reduce the transmission of ground-borne vibration and noise to the structure, helping to ensure the longevity and structural integrity of the building or bridge. Overall, spring vibration isolators are an essential component in many engineering applications to mitigate the negative effects of vibration and noise on equipment, structures, and occupants.

Maintenance Tips for Spring Vibration Isolators in HVAC Systems

Inspect the spring vibration isolators for signs of wear, damage, or corrosion. This includes checking the condition of the springs, housings, and snubbers. Ensure that the isolators are properly aligned and installed according to manufacturer recommendations. Misalignment can lead to premature wear and reduced effectiveness. Clean the isolators regularly to remove any buildup of dirt, debris, or other contaminants that could impact their performance. Check for any excessive movement or sagging in the isolators. This can indicate that they are no longer providing adequate support and may need to be replaced. Monitor the overall condition of the HVAC system and address any issues that could impact the performance of the vibration isolators. Regularly inspect and maintain other components of the HVAC system, such as fans, motors, and ductwork, as these can also impact the performance of the vibration isolators. Consider scheduling routine professional inspections and maintenance to ensure that the vibration isolators are functioning as intended and to address any potential issues before they escalate.

Comparing Different Types of Spring Vibration Isolators for Noise Control

There are several different types of spring vibration isolators commonly used for noise control, each with its own advantages and disadvantages. Some common types include steel coil spring isolators, rubber-in-shear isolators, and elastomeric spring isolators. Steel coil spring isolators are often used in heavy-duty applications and are highly durable, with a high load capacity. However, they can be relatively stiff and may transmit higher frequencies of vibration. Rubber-in-shear isolators provide good isolation at high frequencies and are effective at reducing impact and shock vibrations. However, they may have a lower load capacity and can degrade over time with exposure to oils, chemicals, and UV light. Elastomeric spring isolators combine the benefits of rubber and spring isolation, providing good vibration isolation across a wide frequency range. They are often used in HVAC systems, industrial machinery, and power generation equipment. When comparing different types of spring vibration isolators, it is important to consider factors such as load capacity, frequency range, environmental conditions, and maintenance requirements to determine the most suitable option for a specific noise control application.

The Role of Spring Vibration Isolators in Preventing Structural Damage

Spring vibration isolators play a crucial role in preventing structural damage by effectively isolating the vibration and shock that can be transmitted from machinery or equipment to the building structure. These isolators are designed to absorb and dissipate the energy generated by the equipment, thus reducing the impact on the surrounding structure. By installing spring vibration isolators, the risk of structural damage caused by excessive vibration and shock is significantly minimized. This not only helps protect the integrity of the building and its components but also ensures the safety of occupants and the longevity of the machinery. In addition to preventing structural damage, spring vibration isolators also help improve the overall performance and operation of machinery by reducing noise, increasing equipment lifespan, and decreasing maintenance costs. Overall, these isolators are essential in maintaining the stability and functionality of structures and equipment in industrial, commercial, and residential settings.

Improving Comfort and Stability with Spring Vibration Isolators in Vehicles

Spring vibration isolators are integral components in vehicles that are designed to improve the comfort and stability of the ride. These isolators work by absorbing and dampening the vibrations and shocks that occur while driving, thereby reducing the amount of impact transferred to the vehicle and its occupants. By effectively isolating the vehicle's chassis and suspension system from the engine, drivetrain, and road disturbances, spring vibration isolators help to minimize noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This leads to a smoother and more comfortable ride for passengers, while also enhancing the overall driving experience. In addition to improving comfort, spring vibration isolators also play a crucial role in enhancing the stability and handling of the vehicle. By isolating and controlling the amount of movement between the various components of the vehicle, these isolators help to maintain proper traction and stability, especially during cornering, braking, and sudden maneuvers. Overall, the use of spring vibration isolators in vehicles is essential for optimizing ride comfort and stability, and their design and implementation continue to be a focus for improving the performance of modern automobiles.

In conclusion, spring vibration isolator technology is a highly effective solution for maximizing equipment performance and reducing the impact of vibrations. By using spring vibration isolators, operators can ensure that their equipment operates at its optimal level, while also prolonging its lifespan and minimizing maintenance costs. Investing in spring vibration isolator technology is a sound decision for any industry looking to improve the efficiency and reliability of their machinery.

See also

https://www.gmt-rubber.com/vibration-isolators https://www.rubberfab.com/products/anti-vibration-mounts/

تعليقات

إرسال تعليق